1

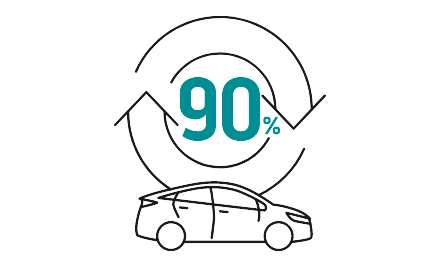

Challenge met: a solution to recycling airbags

While the recycled content in car parts grew to be 90%, airbags and seatbelts continued to be thrown out due to recycling difficulties, with no means available to put them to good use. To recycle airbag offcuts helps achieve our pursuit to raise the recycling rate of car parts.

2

Recycling a high-quality nylon 66 material

Used for airbags, i.e., products meant to save human lives, nylon 66 is a material with an extremely high level of quality to meet strict safety standards and associated criteria.

3

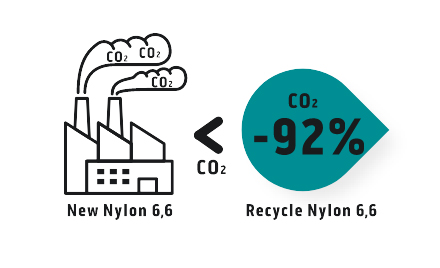

Reducing environmental tolls

ABSSOLOOP is produced through energy-efficient material recycling treatment. It generates 92% less CO2 relative to virgin nylon production, which implies drastically less tolls on the environment. To recycle airbag offcuts helps achieve our pursuit to raise the recycling rate of car parts.